Share it with everyonethere's no need to get shirty with someone because they have an opinion on something that differs from yours

I don't suppose you know the people who write Practical Classics any better than Jon so you could both be wrong as easily as right.

Let's just get as much information as possible out there to help as many people as possible?

Reply With Quote

Reply With Quote

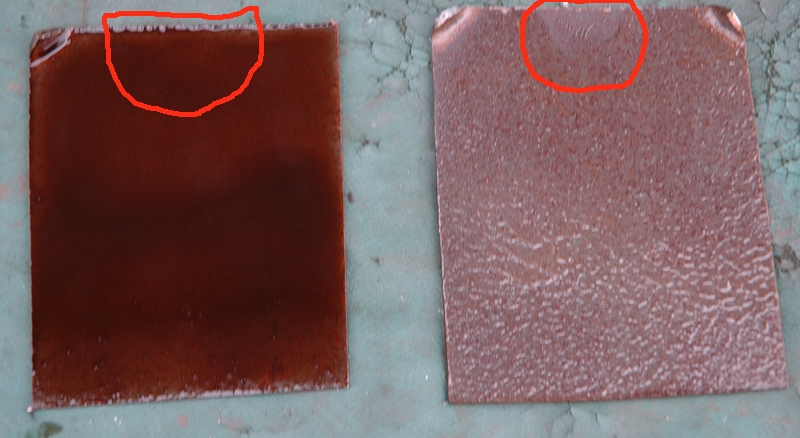

It would be interesting to do the same with Dinitrol to find out which is best

It would be interesting to do the same with Dinitrol to find out which is best

Jon and I have exchanged PM's and I sincerely hope that there are no hard feeling between us

Jon and I have exchanged PM's and I sincerely hope that there are no hard feeling between us

It was done over about 12months iirc. Piles of magazines to wade through, but I'll find it.

It was done over about 12months iirc. Piles of magazines to wade through, but I'll find it.

talked about wax injection products, corrosion removers, paints that remove rust, sealant, anti rust this and protectant that. I have used stone chip in the past and it was about as good as slapping a coat of emulsion on. There are professionals who make a living out of waxoyling cars but I have always had my doubts about it. I posted this some time ago on SXOC

talked about wax injection products, corrosion removers, paints that remove rust, sealant, anti rust this and protectant that. I have used stone chip in the past and it was about as good as slapping a coat of emulsion on. There are professionals who make a living out of waxoyling cars but I have always had my doubts about it. I posted this some time ago on SXOC

) In your testing are you going to throw gravel at the mild steel sections? (to mimic road grit, etc hitting it)

) In your testing are you going to throw gravel at the mild steel sections? (to mimic road grit, etc hitting it)

) It just flaked off. Yep stonechip the sills, chassis rails and floor pan. I will include all the prepping, products and application in the refurb thread (which is being held up by the weather and waiting for MR Postie to arrive with goodies)

) It just flaked off. Yep stonechip the sills, chassis rails and floor pan. I will include all the prepping, products and application in the refurb thread (which is being held up by the weather and waiting for MR Postie to arrive with goodies)