320lbft

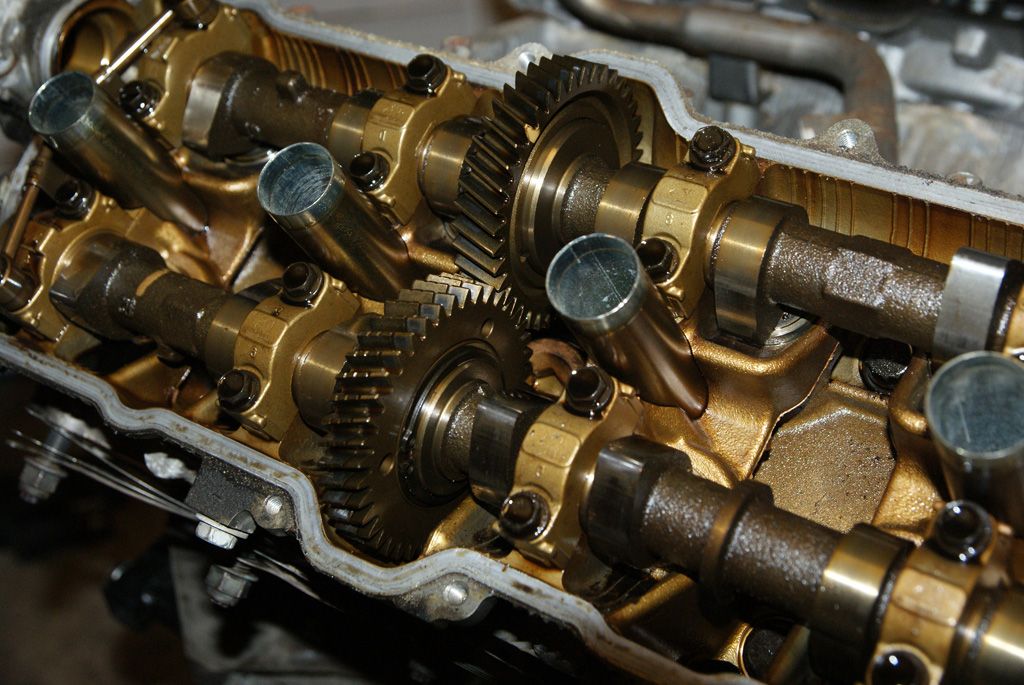

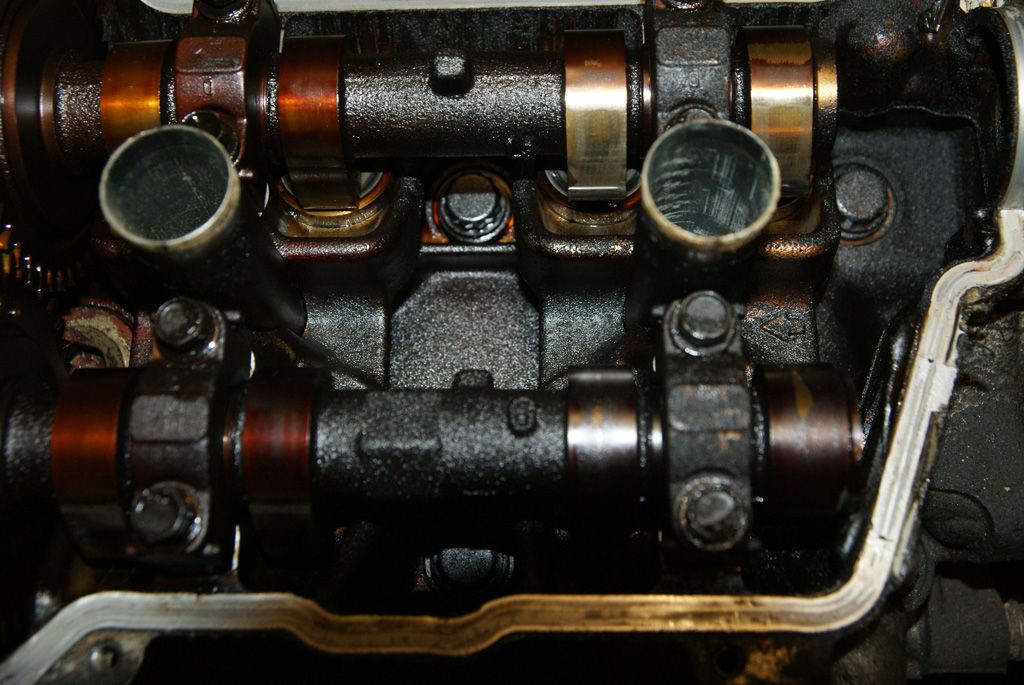

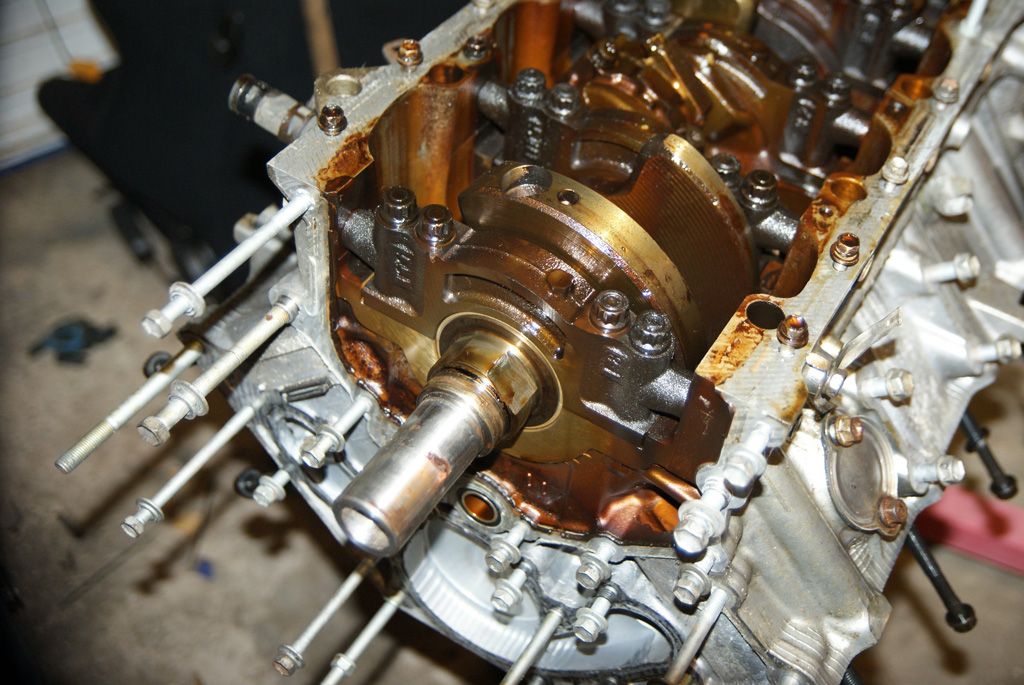

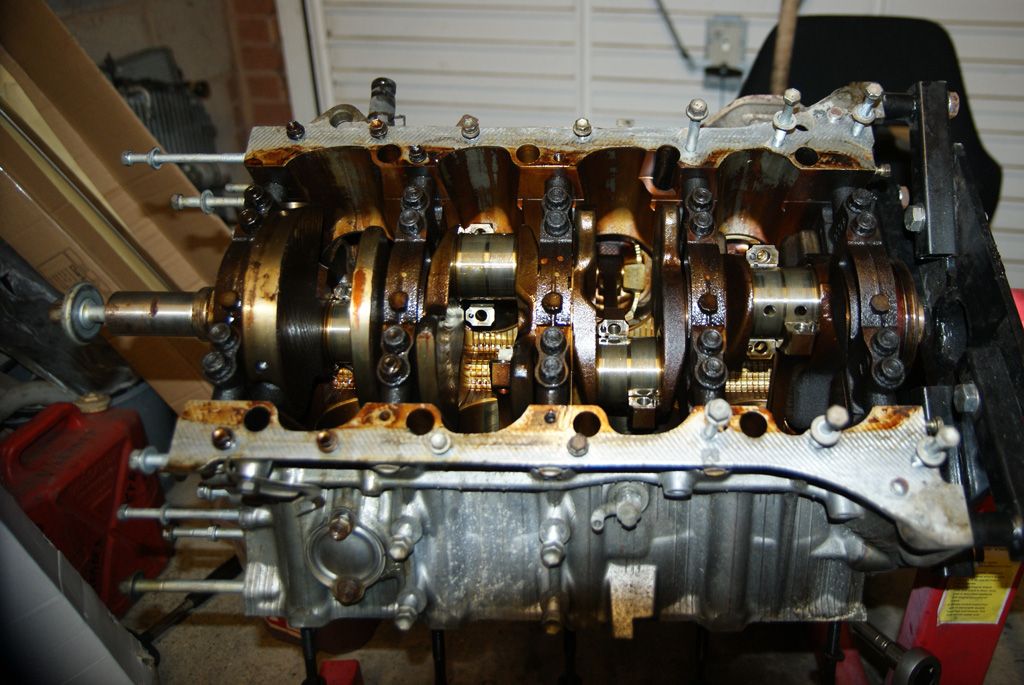

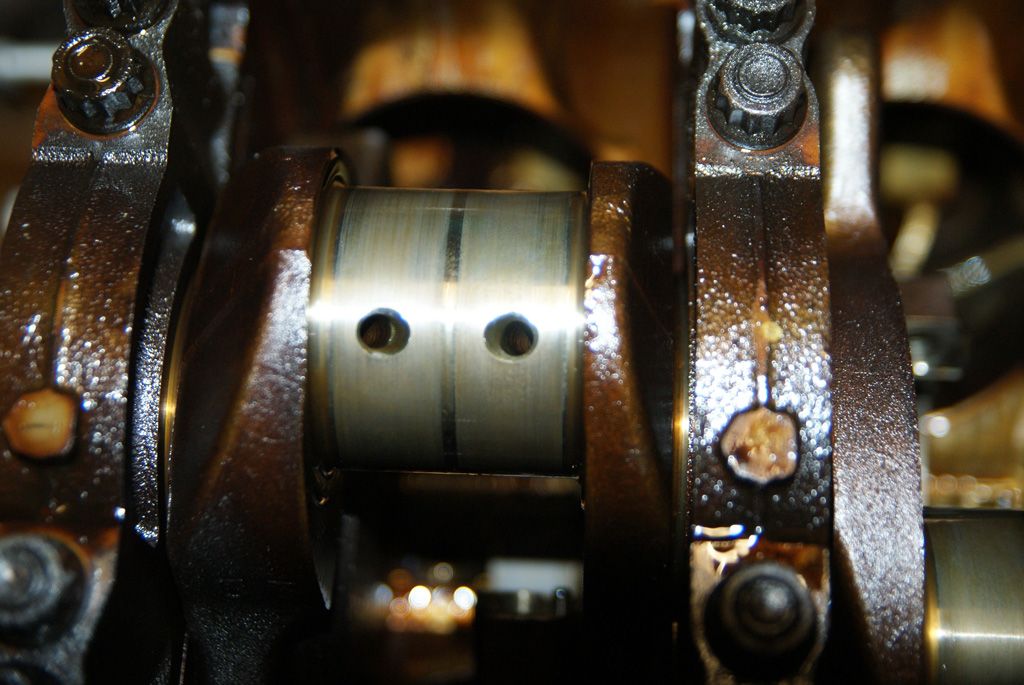

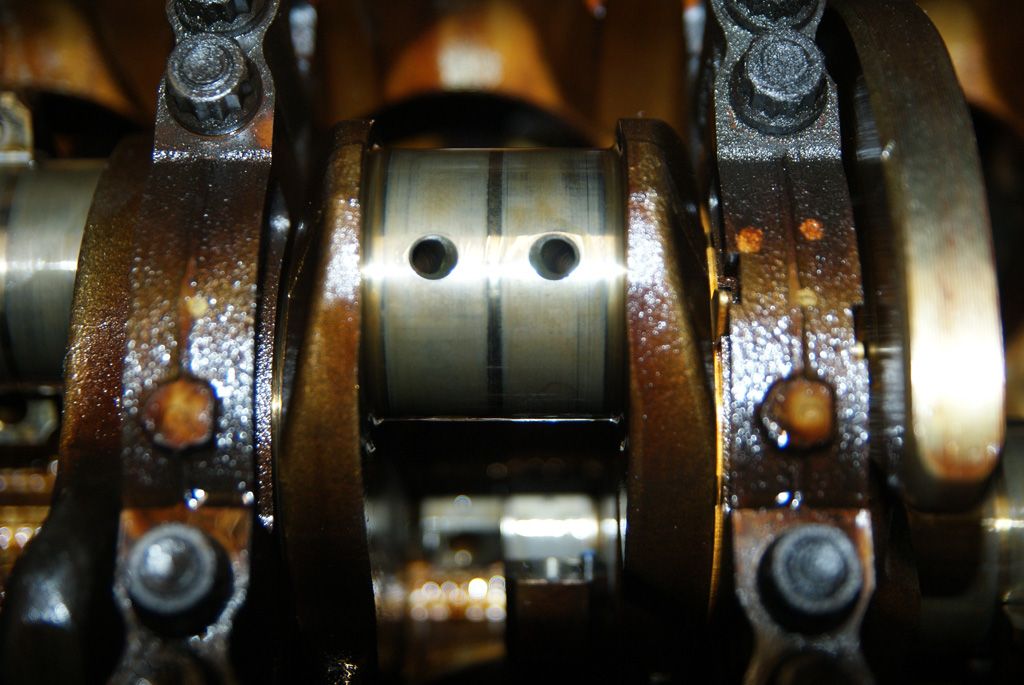

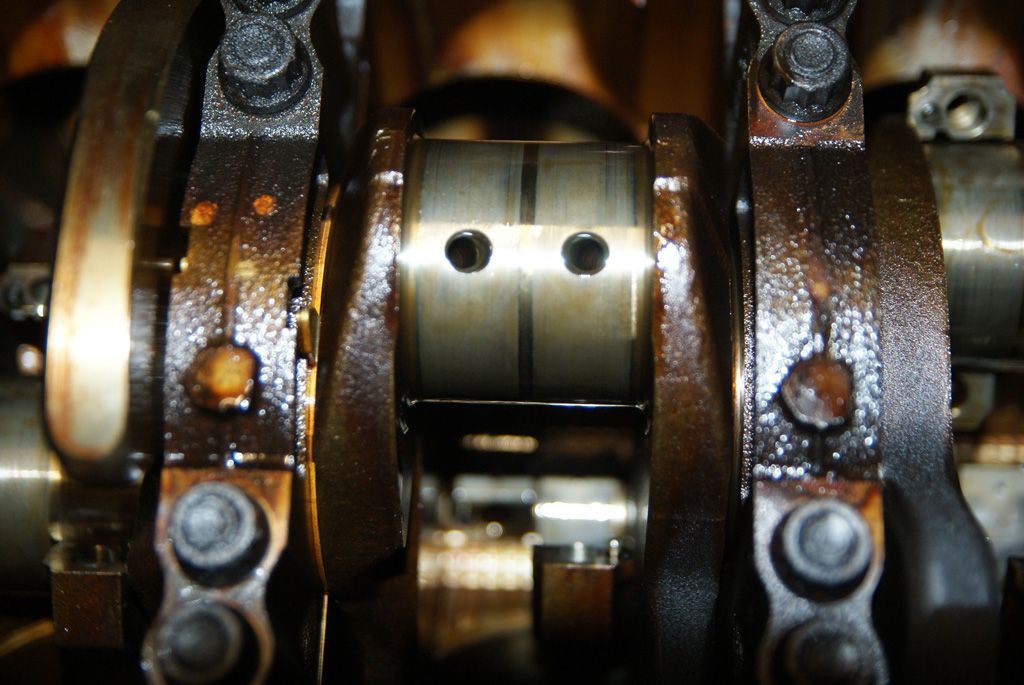

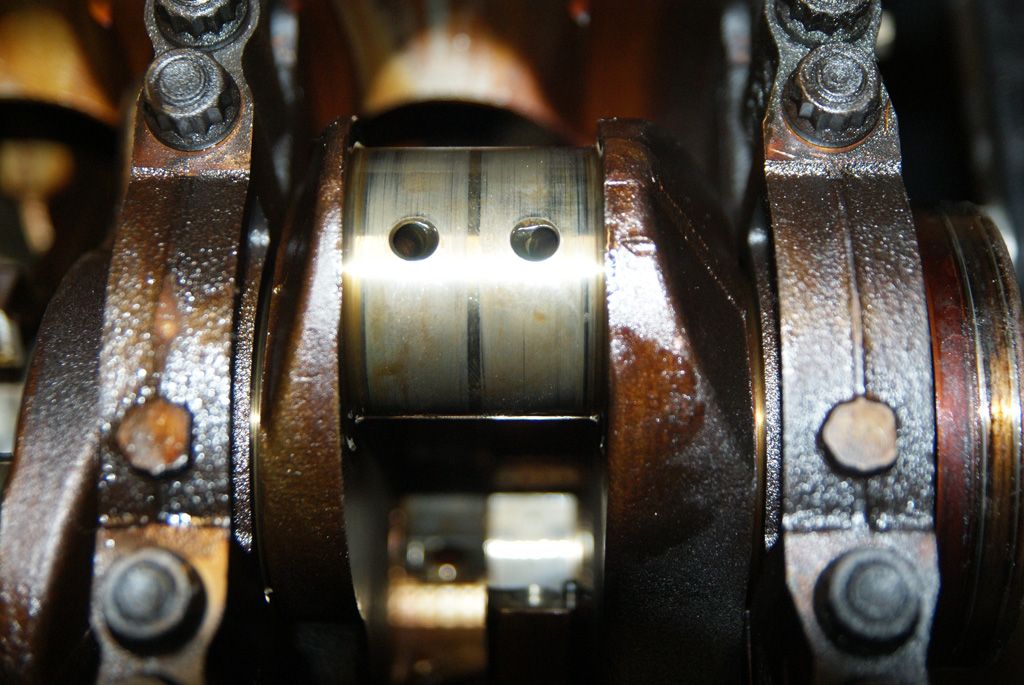

You'll be waiting a while, I'm just doing odd jobs at the moment while I try and scrape some money together! I would like to be able to fork out for pistons, bearings and gasket kit by the summer and get the block put together in the warm months. I'm not bothering with rods even though it's a mid-life block so it has the smaller rods in. That ties up better with it staying NA to keep the mass down so it won't mind revving out to ~7k or more. The heads will take a lot longer, I need to get them flowed properly (I need Cf numbers rather than volume flow for my GT model) and get the cams measured. Then I can fine tune my model and work cams out. I have a couple of options I've put together but the right choice rather depends on how the heads flow out the box and how much of an improvement I can net without going to the effort of pulling the whole port throat up into the injector cavity. I'll put a pic up later that will explain better.

I don't think I will be able to fit equal length 4-2-1 exhausts in without doing something drastic in the car even with the 1.5" primary size I'm thinking of. I can probably work out how much of an effect that will have once I know where I need to compromise.

Reply With Quote

Reply With Quote

which is not entirely unbelievable, even for a not very low ride height when you look at the arm angles. Imagine how bad it is when the car is sat on the deck tucking tyre!

which is not entirely unbelievable, even for a not very low ride height when you look at the arm angles. Imagine how bad it is when the car is sat on the deck tucking tyre!