As a side project, I've been looking into suspension geometry at the front. I had a couple of ideas namely:

- Look at what the geometry is at the moment - how bad is roll centre specifically and what other implications this has

- How much do the stock components weigh?

I've weighed most of the important bits:

- Upright = 6.1 kg

- R33 Caliper = 3.8 kg

- S14 Lower Control Arm = 2.2 kg

- Tension Rod = 1.5 kg

- LS400 Caliper (for reference) = 5.1 kg

I kept hold of the LS400 calipers because they take a bigger disc and pads etc are cheaper with a good selection available - they appear to be popular with the Supra boys as an upgrade. I'm wondering now though if I should be looking at ally Z32 calipers and not worry about cost of pads to benefit from a weight perspective. Here is the two side by side:

I've started drawing something up in CAD for the upright using 6083-T6 (7075 would be nice but is more expensive and a little unnecessary) as the material guideline just to see where I get to. In terms of weight, I'm looking to halve the weight of the uprights which I think I'll exceed because having put together the main body with caliper mounts it was ~800g with the steering arm and balljoint section to add on. I've calculated; very approximately with a tolerance of about 20mm, that I would like to move the lower balljoint by approximately 75mm - which is a huge amount! The implications of doing that are quite huge with respect to scrub radius etc so I need to spend a bit of time thinking about how best to set the geometry. To be clear - I'm not interested in returning the car to "stock" because it has a completely different engine among other things so the boundary conditions for CoG height etc are a bit different to what they were. I have options this way to consider how to make the steering manageable in the event I remove the PAS to facilitate fitment of sexy exhaust manifolds because it's on the drivers side where space is tightest.

If my calcs are even close to right then the front roll centre (assuming the arch sits 45mm above the top of the wheel) is just over 1 meter below the ground

which is not entirely unbelievable, even for a not very low ride height when you look at the arm angles. Imagine how bad it is when the car is sat on the deck tucking tyre!

This is hugely overkill and I'm just keeping myself busy so it might come to nothing. I could be out in the garage playing with the V8, but my oven decided that cooking was no longer its top priority so I'm all out of cash now replacing that

At least this is free!

Reply With Quote

Reply With Quote

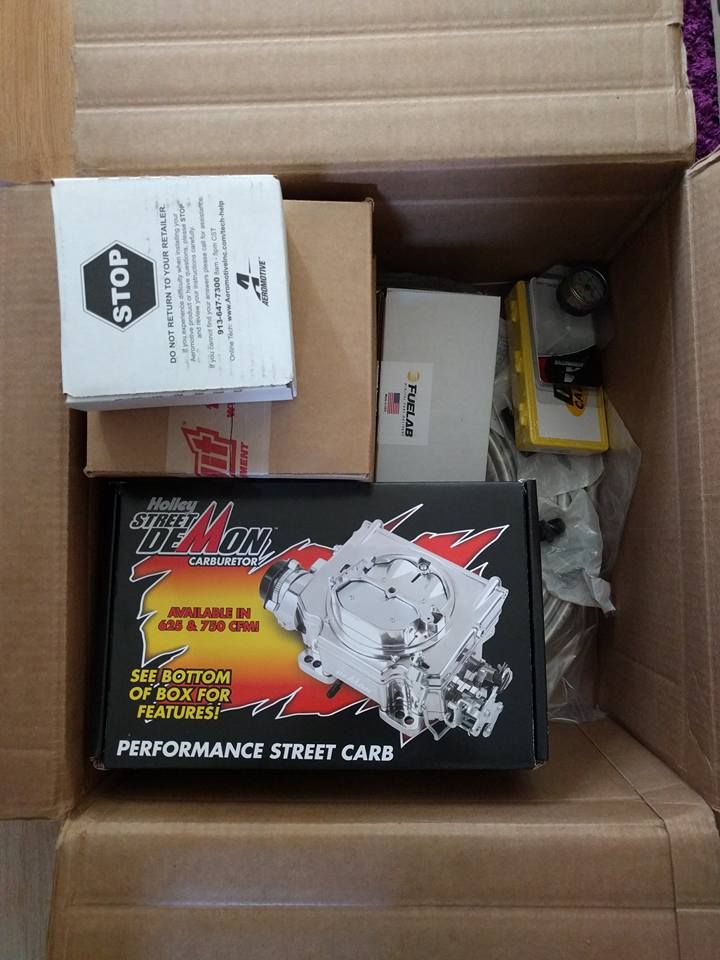

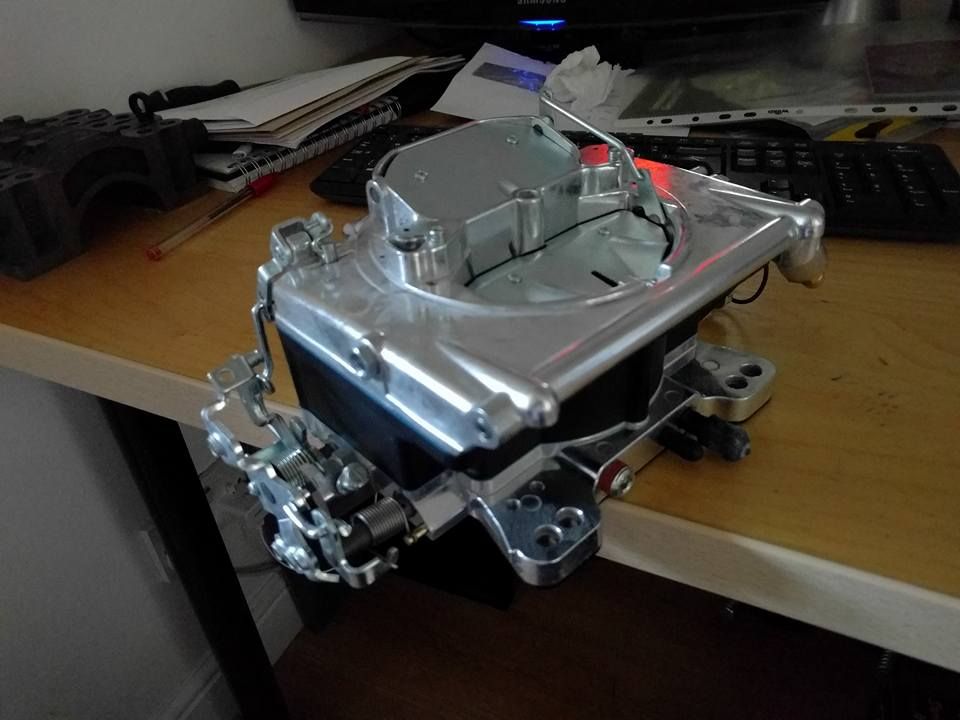

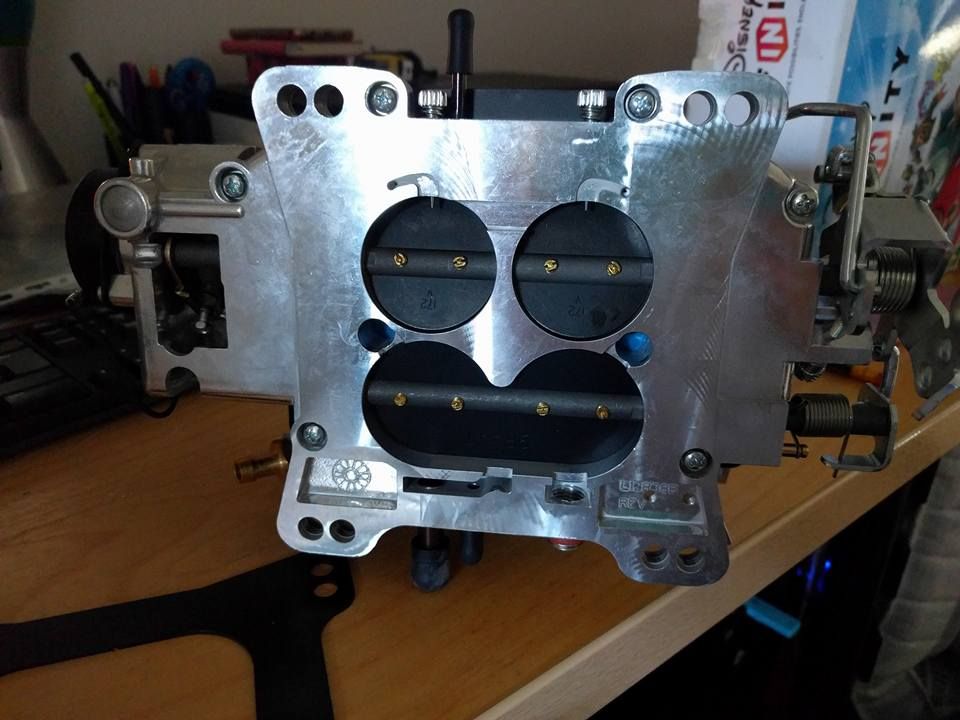

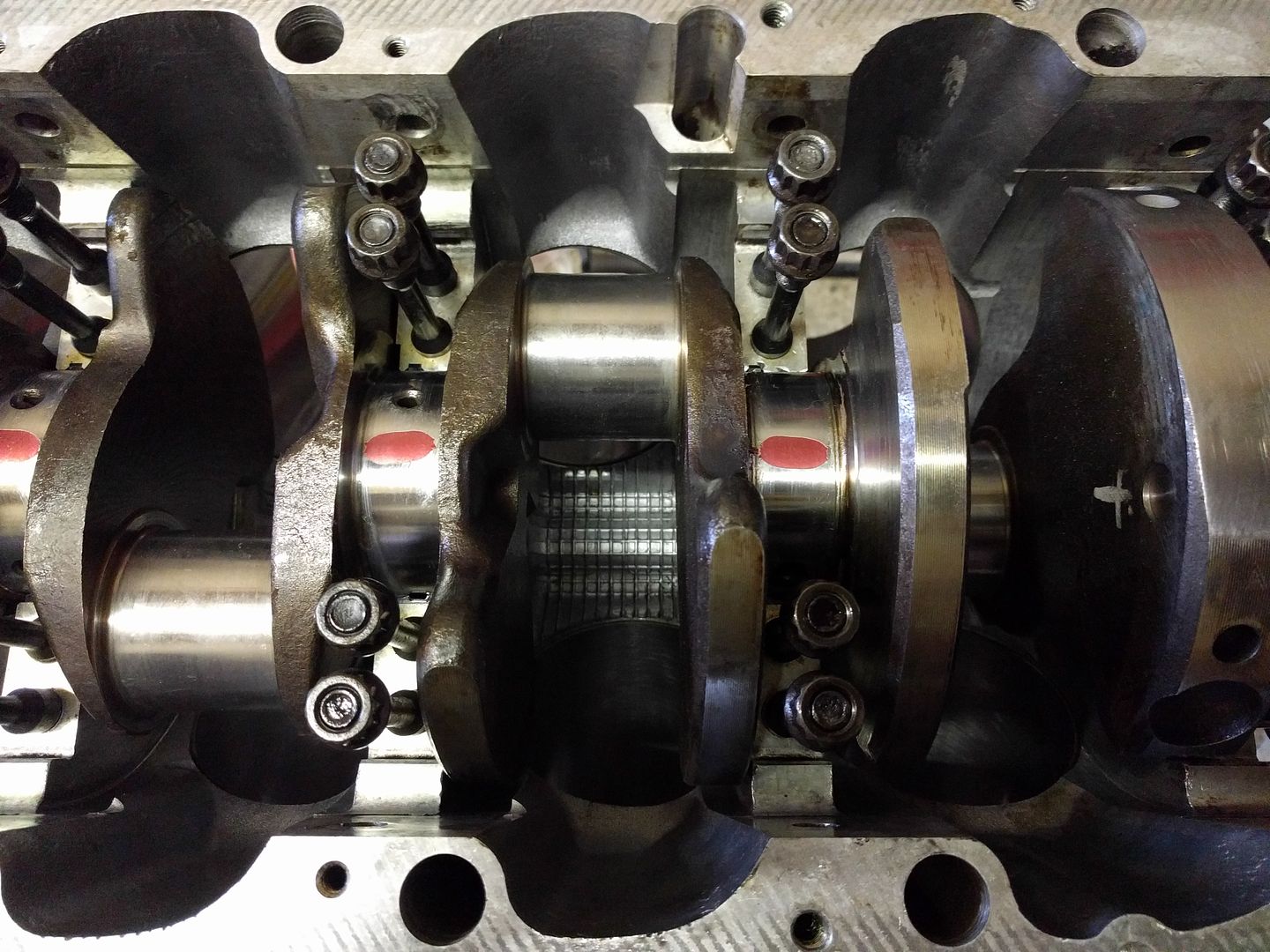

Got everything to rebuild the fuel system from the tank to the engine for less than £1000 from the US, even with the exchange rate going all over the place.

Got everything to rebuild the fuel system from the tank to the engine for less than £1000 from the US, even with the exchange rate going all over the place.

which is not entirely unbelievable, even for a not very low ride height when you look at the arm angles. Imagine how bad it is when the car is sat on the deck tucking tyre!

which is not entirely unbelievable, even for a not very low ride height when you look at the arm angles. Imagine how bad it is when the car is sat on the deck tucking tyre!