-

-

Guest

-

Guest

i was gonna say, WOW that stuff changes the design of the wheels.

That it some cools stuff, Do you do this sort of thing a lot?

-

Guest

-

-

Guest

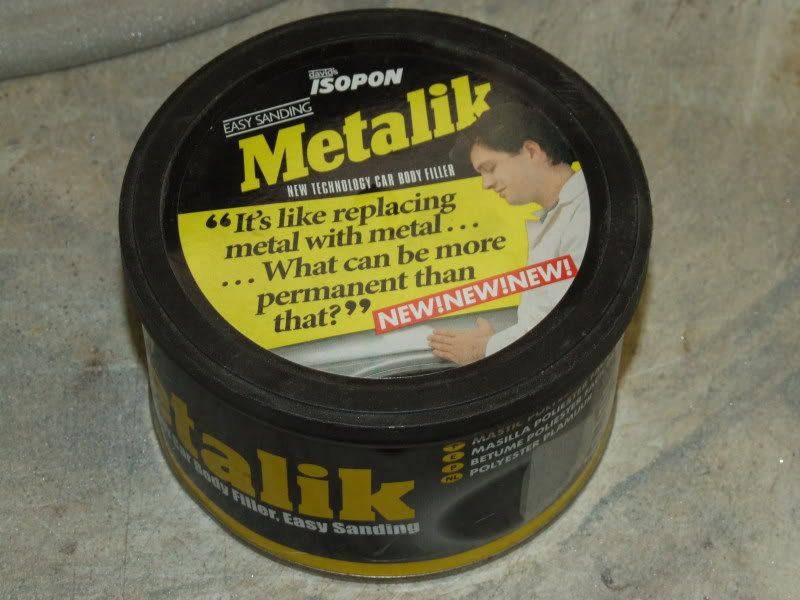

Preperation

The preperation of the wheels takes longer than the blasting. It will take between 10 and 15 minutes to thoroughly prep a non damaged wheel, where a kerbed wheel will take up to 20 minutes.

This wheel required very little prep and just needed some masking up and a light going over with P360 sandpaper.

-

Guest

-

-

Guest

-

Guest

-

-

Guest

-

Guest

very interesting and nice write up. always wondered how how powdercoating was done

-

Guest

-

Guest

-

Guest

Very cool thread, always wondered how it was done!

-

Guest

Very nice.

Does the powder coat always come out at the same thickness all over the piece or does it vary slightly?

Is the wet painting between coatings to allow a specific colour to be applied? ie. I have my wheels paint WKO pearl white but seeing as PCing is a lot more hard wearing is it still possible for them to be done pearl?

-

Guest

How much do you charge for a set of 4 wheels?

-

Guest

Very interesting.  Thanks for sharing.

Thanks for sharing.

-

Guest

This is an awesome thread, I've got some wheels I want to get painted and was thinking of getting them powder coated.

Shame your too far away otherwise I'd get you to do mine.

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Thanks for sharing.

Thanks for sharing.