Turret top cleaned up with a plastic brush in the leccy drill

Can't get into the seams

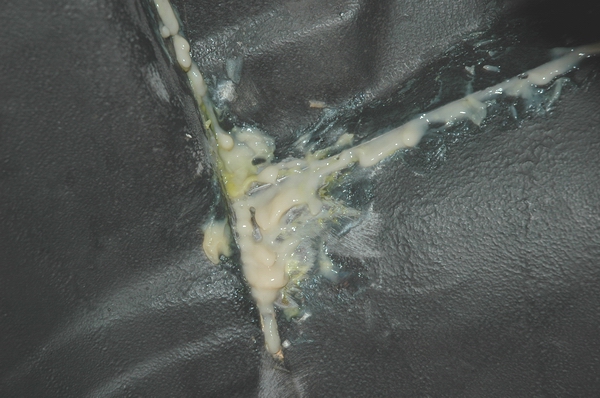

You can see why on this pic

Front of rear arch

Back of rear arch. I carefully opened the joint but can't get in to clean it up

Injecting Deox gel with a syringe

They recommend itís applied 4mm thick. Not easy with a brush so I used the syringe

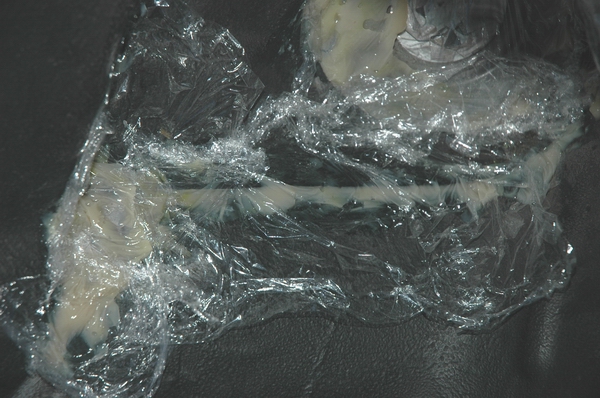

Covered in cling film

Reply With Quote

Reply With Quote

Never seen it before but it's open cell

Never seen it before but it's open cell

Not started on the lower arms and hub jobbies yet. Still thinking about the best plan of attack, or waiting to see what someone else has done

Not started on the lower arms and hub jobbies yet. Still thinking about the best plan of attack, or waiting to see what someone else has done

Thats more or less the whole of the NS chassis leg stripped

Thats more or less the whole of the NS chassis leg stripped

Bit OTT but better to be safe

Bit OTT but better to be safe